With the TYROLIT LIFE Bread Cut, you can easily cut bread in the future and squeezed slices or crumbs will finally be a thing of the past. The sturdy blade with the precise wavy cut is perfect for all types of bread, from soft toast to classic baguettes. The ergonomic shape and the long blade ensure maximum reliability and easy handling. Thanks to the integrated handle cavity, it is possible to guide the 140 g light bread cut cleanly and precisely when cutting.

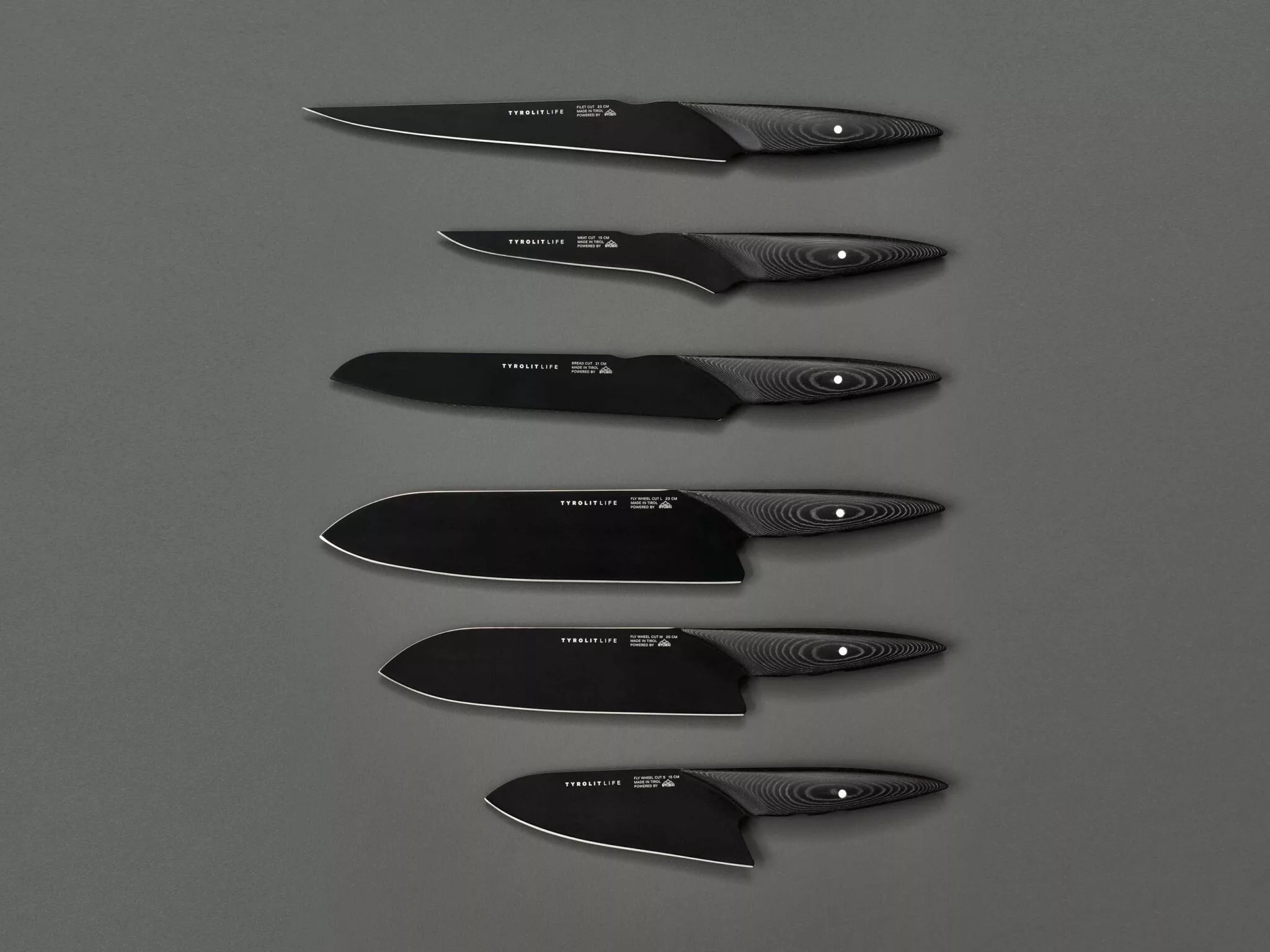

The special coating that distinguishes all knives of the DARKLINE knife series ensures low resistance and high lubricity. This greatly reduces the adhesion of the cut material. Discover our entire bread knife range.