In addition to cutting meat and fish, the TYROLIT LIFE Filet Cut is also suitable for thinly sliced fruits and vegetables. The 120 g lightweight knife has an ideal degree of flexibility due to its geometry and blade length of 23 cm. Thanks to this flexibility and the thin blade of the filleting knife, it can be cut close to the skin or bones.

Bestseller

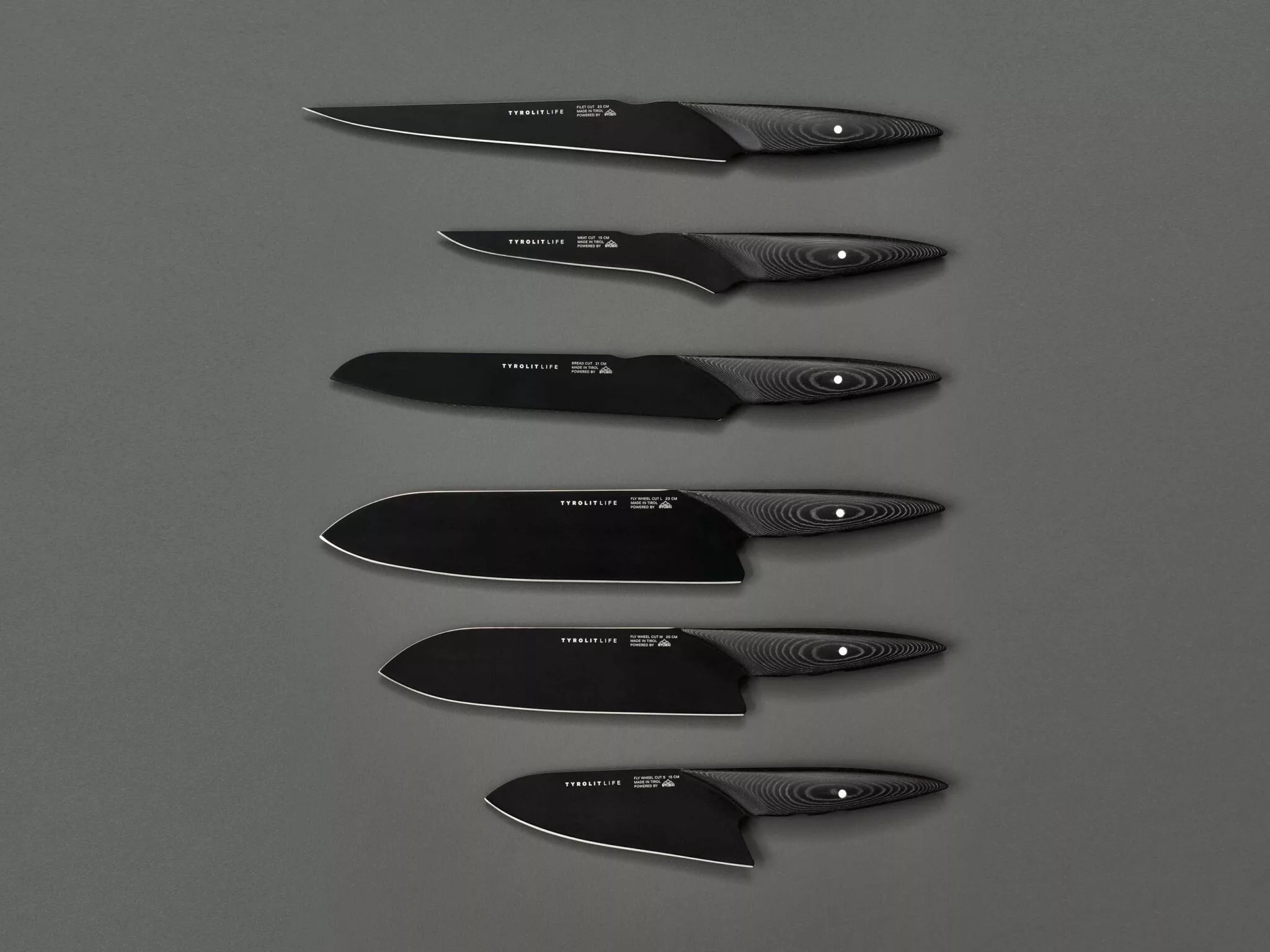

Fillet cut (23 cm)

- Blade Length: 23 cm

- Hardness: 60 HRC (Rockwell Hardness)

- Weight: A light 120 g

- Blade Width: 2 mm at the handle, tapering to 0.6 mm at the tip

- High-End Stainless Chromium Steel with Special Alloy Additions

- Special Coating to Minimize the Adhesion of Cut Materials

- Patented Micarta Handle

- Handcrafted in 64 Steps by Master Artisans

- Ideal Flexibility Due to the Blade’s Length and Geometry

€ 202,42€ 269,88inc. VAT.

available (Delivery time: within 2-4 working days)

Free shipping from 99 €

Free return

Made in Austria

Description

Technical data

Safety instructions

The material

The TYROLIT LIFE Filet Cut features a high-end martensitic stainless steel (60 HRC) with special alloy additives, which provides a high hardness due to its unique microstructure. This steel meets the same high standards required for precision tools or surgical instruments.

The Hardening Process

The steel's deformability is significantly reduced through vacuum hardening at temperatures up to 1050 °C, followed by nitrogen overpressure cooling. After this extreme thermal treatment, the blade is carefully reheated in a process known as "tempering." This step ensures the exact hardness level and optimal flexibility of the blad

The cut of the blade

In the grinding shop, the blade blanks are pre-ground using specialized grinding stones under strong cooling conditions. The blades are then polished and the edges are refined through multiple grinding stages. The final honing is achieved with particularly hard CBN (cubic boron nitride) grinding wheels.

The coating

The black coating, adopted from the tool industry, provides exceptionally high glide performance while cutting and gives the knife its distinctive look.

The handle

The handle scales are pre-made from Micarta and then three-dimensionally machined on a multi-axis CNC machine. The ergonomic shape of the handles is achieved through meticulous hand grinding and polishing before they are press-fitted airtight with the steel and permanently bonded.

The engraving & the finishing touches

The contour of the knife is finely polished, creating the characteristic effect of the elegant interplay between the high-gloss metal and the deep black blade. All edges of the knife, except for the cutting edge, are rounded. The laser engraving remains visible for the lifetime of the knife. Each individual knife is meticulously polished and inspected by the master after the final sharpening. Only then is it released for sale. This ensures that every TYROLIT LIFE product maintains consistent quality with each piece.